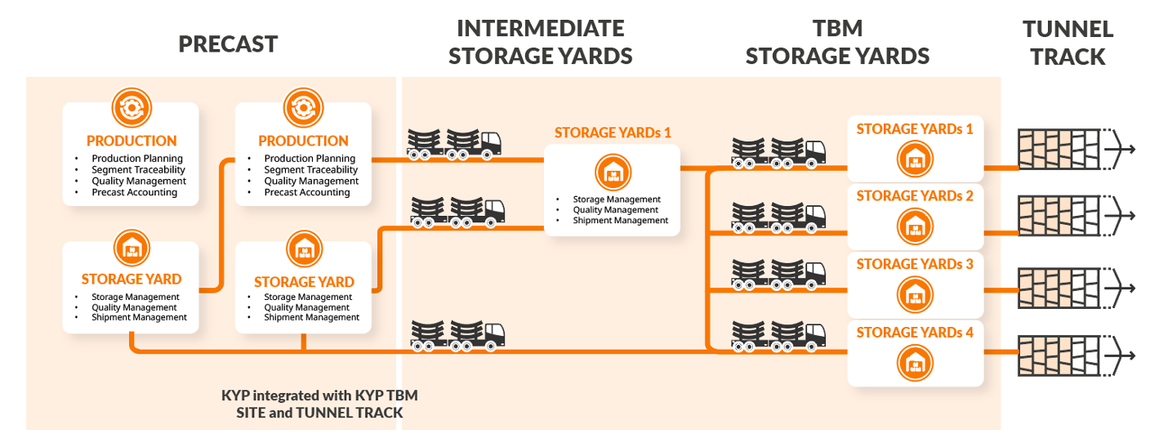

KYP is the must powerful Tunnel Segment Management System in the market

A unique platform from the Precast to the TBM

KYP main features

Quality and traceability

Automation Integration System

Automation of different phases of the process and integration with existing third party hardware and software

Segment Traceability

Quality

Control

Controling the quality process with the aim of reducing operator errors.

The operator is required to verify the completion of a series of activities

in order to proceed to the next phase.

Through the use of barcode guns / readers configured

with the precast management system KYP provides:

- Type of mould used

- Start and End of production

- Traceability of iron cage (with documents and certificates)

- Traceability of integrated parts (with documents and certificates)

- Verification of bill of materials

- Start and End of the casting process

- Management and traceability of segment defects with photos and a customizable check list

Monitoring

KYP

supports the production phases and processes of concrete segments in a carousel production or stationary moulds.

It provides a complete documentation and traceability of the production process from the insertion of the iron reinforcement, to the storage and curing of the segments.

Identification

The identification of each mould and each segment is possible with:

- the application of strong labels with univocal barcodes

- the insertion of RFID tags inside.

KPI Dashboard

Live reporting

- how many segments are made and shipped every day;

- how many segments are in stock and how many are cured;

- number of segments with

defect or

wasted.

Productivity

- Production Dashboard allows constant monitoring of the production plant with key performance indicators (KPI) in real time.

- Export Data of Traceability to Excel.

Storage and Delivery from Precast to TBM

Custom Plant Map

Customizable map

according to the warehouse layout

Data updated in real time

Offline functioning applications, there is no need for wi-fi coverage of the storage area.

Custom Delivery Note

The operator in the warehouse can automatically prepare the delivery notes

using the precast management system KYP saving time and reducing the risk of errors.

Special Features

Plant Maintenance

Digital Helmet - Remote Support

With the Digital Helmet, experts can provide visual guidance by superimposing instructions on the technicians head-up display.

- Hands free work through Wireless helmet camera

- Vocal commands to read barcodes or to take frontal screenshots

- Visor projection allows users to see photos, schematics, and product manuals from remote experts.

Plant Prev entive Maintenance

Increase the useful life of your equipment by utilizing KYP Asset Manager module.

- Track Plant Equipment

- Record Acquisition Data

- Create Maintenance Plans

- Create Maintenance Work Orders

Consumables and Devices

Printers and Labels

The identification

of each mould and each segment is possible with the application of labels

with univocal barcodes.

Digitalnology provides printers

and reinforced labels for segments and cages.

RFID Tags

The identification of each mould and each segment is also possible with:

- RFID Tag

- NFC Tag

- Custom Special Tag

- Dual Technology Special Tag

Barcode Readers

Labels with univocal barcodes can be read by the portable Barcode Guns. With just a few simple steps, the guns can be used by the operators throughout the chain.

- Long Range Guns

- Wi-Fi and LTE connection

- Android System

- Zebra, Datalogic, Honeywell

DIGITALNOLOGY

Contact Us

To request more information fill in the form below or call us on

+39 0362827569